Metal 3D Printing for Energy Industry

Many oil, gas and geothermal companies have accepted that additive manufacturing will play a key part in the future of their businesses. Although it’s adoption in this sector has been slow, they realise the importance of designing lighter and replacement parts that don’t sacrifice strength or quality.

Metal 3D printing cuts timescales when producing new prototypes and printing spare parts. Complex shapes can be achieved easily for impellers, turbines and structural components, especially where minimum weight and maximum strength are key.

We collaborate with numerous companies in these industries and their preferred metal of choice is Inconel 718. That is because it can be used at temperatures between -252c and 704c, it has good tensile strength and can exceed the mechanical properties of its cast and wrought counterparts.

CASE STUDY

Confidential Client

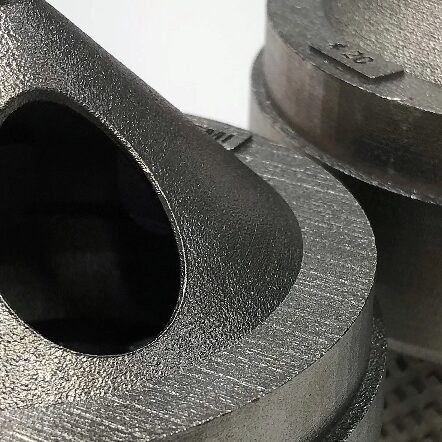

These are examples of structural components for use with carbon fibre tube for the Oil and Gas industry. They are printed in Inconel 718 and weigh 1kg each

Quotes from Bill White, Aeromotors

“I have found RAM3D to be collaborative, helpful, and interested in the outcome of their work, which is a real attribute in the ongoing design and modelling of componentry that suits their processes. This makes for very predictable repeatability, which is a critical element of series or volume production."